WOODEN COOLING TOWER

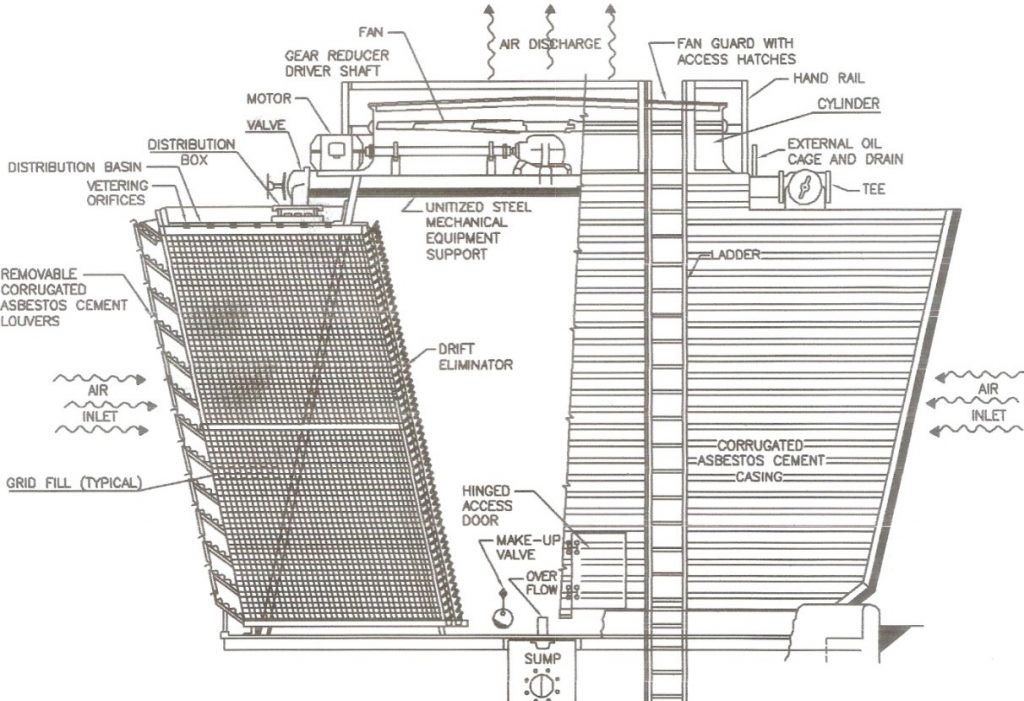

Available In Induced Draft Cross Flow and Counter Flow Design Cooling Towers

There are a total of 107 models available under single cell configuration. Multi-cell configurations are provided to offer flexibility of operations and also to meet increased cooling requirements. Wooden Cooling Towers are supplied with treated wood construction, which is pressure treated with Copper Chromate Arsenic. Structural design for operational load and wind pressure of 30 psf. is taken into consideration.

CCA (copper chromate arsenic) treated Wood Cooling Towers have proven themselves the world over. Water handling capacity ranges from 45 M3/hr. to 5000 M3/hr. per cell capacity. Fan diameter varies from 1500 mm to 10000 mm. Different models have different Air Travels, Fill height, Fill pattern, Fan diameter, etc. in crossflow design AND varied Fill height, Fill design, etc. in counterflow design.

Details Provided on Get your Quotation

Available in:

Class 4 (11 models), Class 9 (16 models), Class 10 (16 models), Class 15 (16 models),

Class 18 (8 models), Class 500 (12 models), Class 600 (12 models), Class 400 (16 models)

Salient items giving materials of construction :

| ITEM | MATERIAL OF CONSTRUCTION |

| Structure | Treated Wood |

| Fill | Treated Wood / PVC |

| Fill Support | GRP grids / SS. grids |

| Drift eliminator | PVC blades |

| Drift eliminator support | PP. spacers |

| Structural connector | FRP rings |

| Nozzle | Polypropylene (PP) |

| Hardwares | HDG.MS. /SS. |

| Nails | Screw Shank SS. |

| Fan assembly | Cast aluminium alloy / GRP bladed |

| Fan cylinder | FRP |

| Gearbox | Spiral bevel |

| Drive shaft | Floating HDG.MS |

| Casing & louvers | Corrugated AC. sheet /Corrugated FRP sheet |

| Electric motor | To suit country specific |

| Cold water basin | RCC(by purchaser-drawing provided) |

| ITEM | MATERIAL OF CONSTRUCTION |

| Structure | Treated Wood |

| Fill | Treated Wood / PVC |

| Fill Support | GRP grids / SS. grids |

| Drift eliminator | PVC blades |

| Drift eliminator support | PP. spacers |

| Structural connector | FRP rings |

| Nozzle | Polypropylene (PP) |

| Hardwares | HDG.MS. /SS. |

| Nails | Screw Shank SS. |

| Fan assembly | Cast aluminium alloy / GRP bladed |

| Fan cylinder | FRP |

| Gearbox | Spiral bevel |

| Drive shaft | Floating HDG.MS |

| Casing & louvers | Corrugated AC. sheet /Corrugated FRP sheet |

| Electric motor | To suit country specific |

| Cold water basin | RCC(by purchaser-drawing provided) |